This is the story of how I got a bass guitar.

I was sick, laid up on the couch. I was also in a stage of life where I lacked funds for much. One of my favorite pastimes is to scour Craigslist (and similar sites) for good deals on instruments. One of the advantages of being sick is the ability to check Craigslist posts frequently. When a good deal pops up, there’s a much greater chance you’ll get it if you’re the first to respond. So when I saw an accordion listed for $35 I jumped on that fast! Was I looking for an accordion? No, certainly not. But did I NEED an accordion for just $35? Absolutely! The key bed wasn’t level. Some of the keys were angled up an inch higher than the rest. Other keys weren’t as bad, but “level” would not have been a term I used to describe them. But I’m handy, and it was only $35. So I purchased an accordion.

I found that the keys on the accordion were attached to metal bars on fulcrums to open and shut reed valves. The reason the keybed wasn’t level was because most of these bars were bent a little bit. So I bent them all into the position I thought they should be in. The advantage of working on a cheap instrument is the knowledge that the worst thing you could possibly do is lose $35. But I didn’t wreck it. My idea worked exactly as planned! Now all the keys worked properly. The straps for the accordion were not great, so I bought a more comfortable set of straps for…$40. I know, it didn’t feel quite right, but it made a world of difference, and now I had a fully functional accordion for a grand total of $75. I was happy.

This accordion became a centerpiece of my band for some time. I played guitar, but also accordion. It also featured in a friend’s side project (Brown Bear, Brown Bear). But as time went on, I became disenfranchised with some of the limitations of the accordion. I had to have a mic perfectly positioned and I had to stand very still while playing so as to pick up the sound well enough. You have to understand, I’m not much of a mover on stage to begin with; but I was beginning to feel stifled by the stillness that was required of me. So I found a way to mount a microphone on the instrument itself. I screwed in a rectangular metal plate (it came from a light fixture) with screws and holes that already existed on the accordion (i.e. no permanent modification) and used a special mic mount to attach a mic to the plate. It wasn’t the most aesthetically pleasing solution, but it was functional!

Eventually, even this superb mic-mounting creation was not enough to satisfy me. I could move around, but the sound captured was not as ideal as it could be. Some accordions I had seen had 1/4″ outputs just like guitars…I wanted an accordion like that. Microphones on the inside of the instrument capture the whole sound and didn’t require any modification on my end. This would be cool. As this was some years later, I had more funds available. New accordions that could function this way cost in the thousands of dollars. This was more than I had. But I found older accordions from the 70s and 80s that could do what I wanted. Eventually, I settled on an Iorio Model G Accorgan. It was an accordion with a 1/4″ output, but it also came with a tone box that would allow me to play organ sounds without using the bellows. I found it on eBay for $700. If you’re thinking that $700 is a lot for a decades old accordion…you’re right, it is. But I had traveled down the hole of “what can I get with the money I have?” and this was the conclusion I landed on. Sometimes I make really good purchases like buying an accordion for $35. Other times I don’t. So it goes.

The accorgan came in the mail and I was elated. I sold my first accordion for $125 to help offset the cost. The new accordion did exactly what I wanted it to…but it was bigger than my original accordion, and substantially heavier. The weight of the decision I had made hung on my shoulders every time I played the accorgan at a show. The tone box was large and heavy. I never actually took it to a show. I only used the accorgan as an accordion. After a few years I decided to part ways with the accorgan as it was very heavy and took up a lot of space. I had come to use it infrequently and wanted to fund other musical pursuits. Specifically, a bass guitar. So I listed the accorgan for sale online.

The accorgan did not sell quickly, but I had some other money saved up and started to look for a bass guitar. What I wanted was a Fender Jazz Bass that was Made in Mexico. These basses run around $400 used. I had close to that, but I wasn’t quite ready to spend that much without having sold the accorgan. So I kept my eye out for a good deal…and boy did I ever find one. Someone was selling a lot of gear together, including a Fender MIM Jazz Bass, for $400 total. The package included the bass, an electric guitar, a Marshall head and cab, a practice amp, two microphones and a midi controller. So I could purchase all of it, keep the bass, and sell the rest. This was a grand plan.

I reached out to the seller, expressing my interest. He was ready to get rid of the gear and even willing to meet at my place with all of it. Fantastic! The guy shows up a few hours later, I put all the gear in my garage and give him the cash. Done deal! I’m so excited!

The gear is a little dirty/dusty. Maybe has a little smell to it as well. Whatever, that’s what garages are for! I let things air out for the evening and I will work on cleaning it all the next day. An hour later I come out to the garage for an unrelated reason and fully realize the smell…it’s pot. My entire garage smells like pot. Like maybe I could get a contact high from how much I can smell the pot in my garage. This is bad! This is NOT what I wanted. So I crack the garage door and side door and set up a fan to blow on the instruments. Maybe if I let it air out overnight it will be better.

Morning came and I went to check on my new gear. The garage smelled better since the doors had been left open, but none of the gear passed the sniff test. It was still bad. In a defiant act of frustration I took all of the gear out to my back shed. The shed is well ventilated, meaning the smell wouldn’t linger in there; and it was out of the way, meaning I wouldn’t have to constantly see this mistake that I made.

Time, and frustration, passed and I slowly brought each piece inside and cleaned it. I no longer intended to keep the bass…I couldn’t handle the constant reminder of this deal, and I could never quite shake the feeling that maybe I could still smell the pot, despite having cleaned it very well. In the end, after a total of maybe six months, I cleaned and sold all of the gear for a total of $650. The last piece to sell absolved all of my ill feelings towards the situation. The extra $250 in my pocket actually made me feel pretty positive about the whole thing. Now, maybe I can find a new (used) bass and still have some money leftover.

Over the months of listing my accorgan for sale, I got no real bites. I lowered the price regularly and had brought it down to $300. I said I would accept trades for a bass guitar as well. Queue a new email with someone offering their bass for my accorgan. It wasn’t the make/model I was hoping for, but worst case scenario was that I could sell the bass if I didn’t like it. So I met up to make a trade.

The bass had been sitting on a stand, unused, for about 15 years. The neck was badly bent due to the string tension. But I liked the feel of it in general, and it seemed to sound decent as well. I’ve messed with instrument necks before…I could probably fix this. But even if I couldn’t, it’s not like people were knocking down the door to buy my accorgan. This felt like a fair trade of instruments that were unwanted by their respective owners. So we made the trade with no extra cash involved. I was the proud owner of a Kramer Focus 7000.

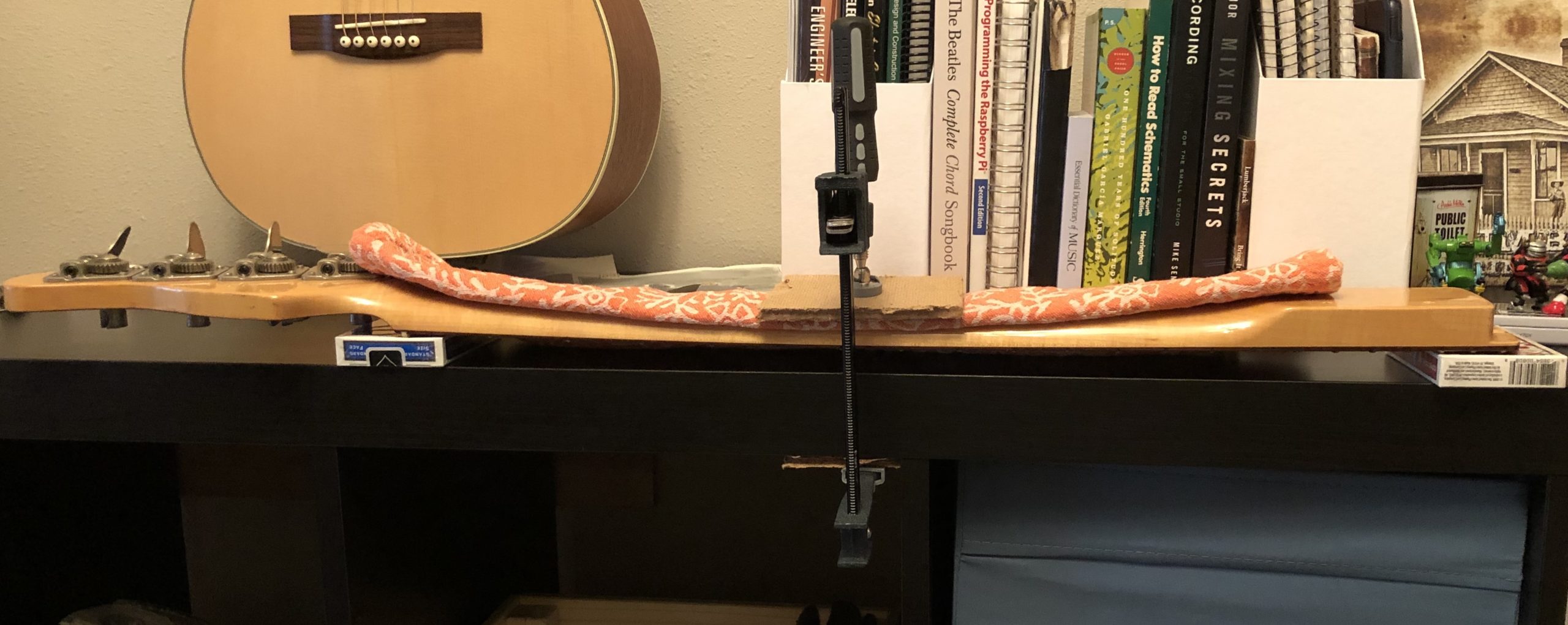

I began operations on the bass neck the next day. Truss rod access was located on the body end of the neck, so I unbolted the neck and made my first adjustment. I put the neck back on and tested it out. The adjustment wasn’t enough, so I tried again. By the fifth or sixth effort, I had maxed out the adjustments that could be made, but the neck was still bent. So I do what I always do in situations like these…I consulted the internet. The internet kindly told me that I could add a washer onto the truss rod to give myself the ability to adjust the neck further. It also told me to clamp the neck in the opposite-bowed position to help train it into place as well as making it easier to adjust the truss rod.

I didn’t own any nuts that were made for truss rods. So I went out to my garage to see what I could find. I found a nut that was close to the right size, but the hole wasn’t large enough for the rod and the outside was slightly too big to fit in the hole of the neck. Using a file and a drill I morphed a regular nut into the perfect truss rod nut for my bass guitar. I was able to adjust the neck-just barely-into a straight position. I attached the neck back onto the bass and it has been in good working condition for nearly a year now. And that’s the story of how I got a bass guitar.

I don’t own all the fancy tools that they do in professional luthier shops, but I found something that would work. This setup required two decks of playing cards, a clamp, a towel and a couple pieces of fiber board. Main goals were to train the bass neck in a new direction without leaving any marks on my shelving unit. I’m not saying that you SHOULD do this…but I made it work with what I had. Be creative!

The video below features the bass from the story. I’m very happy playing it, as you can tell! I may get a different bass someday, but I will never forget my Kramer Focus 7000.